Materials Guide & Example Prints

Materials

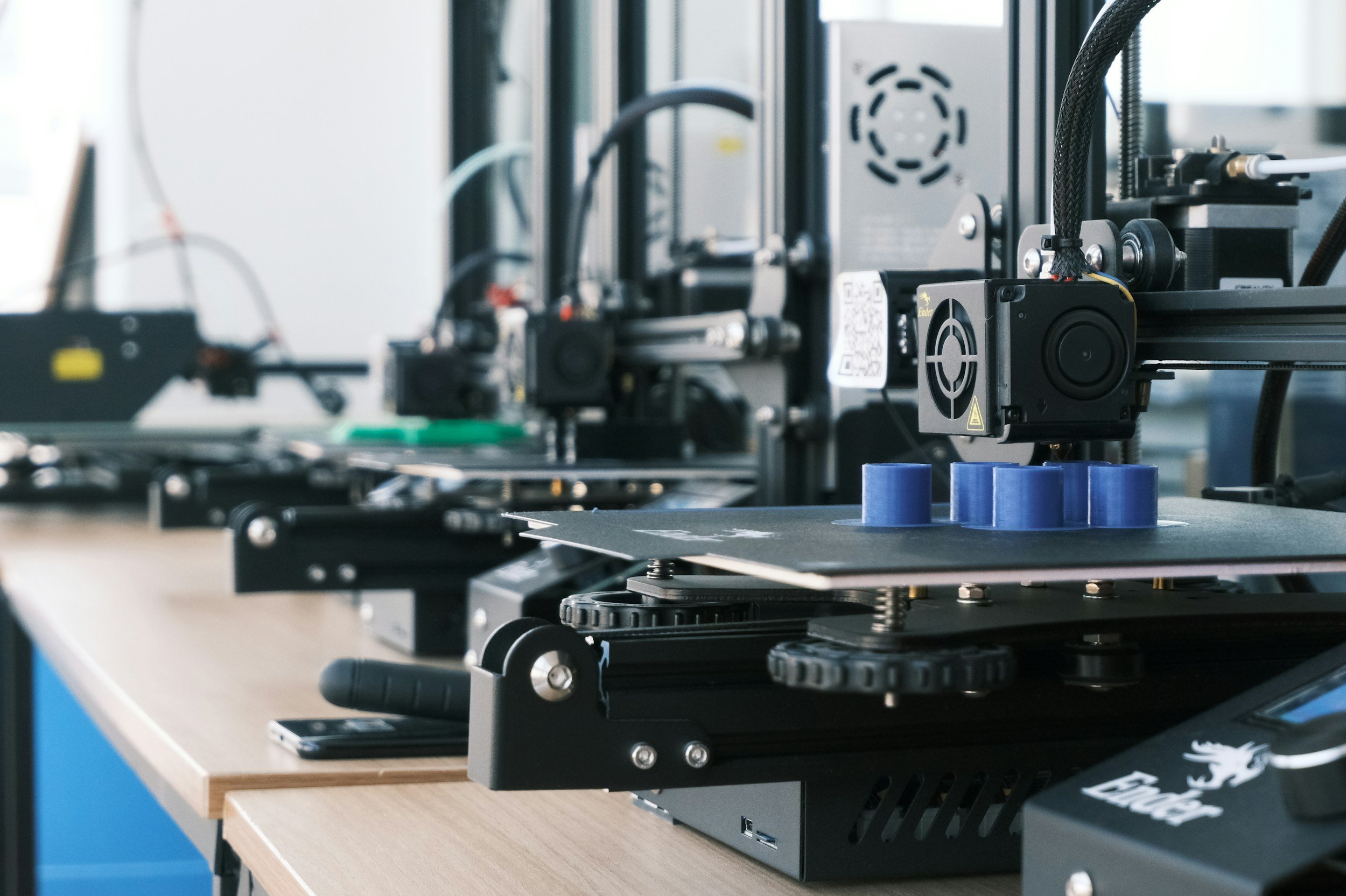

We recommend Fiber Nylon for most parts. Parts are custom-made to-order and 3D printed with high quality materials and printers.

Fiber Nylon

The strongest material to make airsoft parts with. Extremely durable, impact resistant, rigid, scratch resistant, and lightweight. Filled with carbon fiber for black color or glass fiber for other colors. We use a premium grade of nylon called PA12 which does not get soft when exposed to humidity like other nylons. Suitable for all temperatures (up to 380F/194C!) and weather conditions. Rough textured surface with matte finish. 90-day warranty on breakage. Datasheet (for black).

Colors in stock and ready to print: black, silver, desert tan, OD green, red, blue

PLA+

Very common material for making affordable airsoft parts, but less durable than Fiber Nylon. PLA+ has better impact strength than regular PLA. Parts will be printed with extra walls and infill, but there is still a risk of cracking from strong impacts or warping in high temperatures (>90F/32C). Smooth surface with a satin finish. No warranty on breakage. Datasheet.

Colors in stock and ready to print: black

Available on request (+$25): Any color you want with shiny, matte, gradient, sparkle, glow-in-the-dark, wood effect, or other finishes.

Other custom materials available on request (TPU, polycarbonate, PETG).

Project Gallery

Here are some example prints we’ve done recently. We guarantee high quality and high strength parts.

All parts shown here are printed in Fiber Nylon.